Industrial Electronic Scale Chip Model

In the fields of industrial automation and intelligence, industrial control (IC) electronic scales play a crucial role as essential measurement tools. They are widely used in industries such as logistics, warehousing, production lines, and precision measurement. To ensure the accuracy and reliability of these scales, chips, as core components, are of vital importance. IC electronic scale chips need to have features such as high precision, low power consumption, and strong anti-interference capabilities to operate stably in harsh industrial environments. This article introduces some common models of IC electronic scale chips and how to select the right chip based on specific requirements.

1. Basic Requirements for IC Electronic Scale Chips

Electronic scale chips are primarily responsible for processing sensor signals, data conversion, and output, and they need to meet the following performance criteria:

- High Precision Data Conversion: Electronic scales need to convert weight data into digital signals accurately, requiring chips with high-precision Analog-to-Digital Conversion (ADC) capabilities.

- Low Noise and High Anti-Interference: Industrial environments often have high levels of electromagnetic interference and noise, so chips need to effectively suppress noise and ensure stable data transmission.

- Stable Signal Processing Capability: The chip must be capable of maintaining stability in long-term, high-load operating environments, avoiding data drift or distortion.

- Low Power Consumption: While most electronic scales don't operate continuously 24 hours a day, low power consumption remains an important consideration, especially for portable electronic scales.

- High Compatibility: IC electronic scales often need to interface with multiple sensors and external devices, so the chip's interfaces and protocols should have high compatibility.

2. Common IC Electronic Scale Chip Models

Below are some common IC electronic scale chip models that cover various aspects, from analog front-end to digital signal processing:

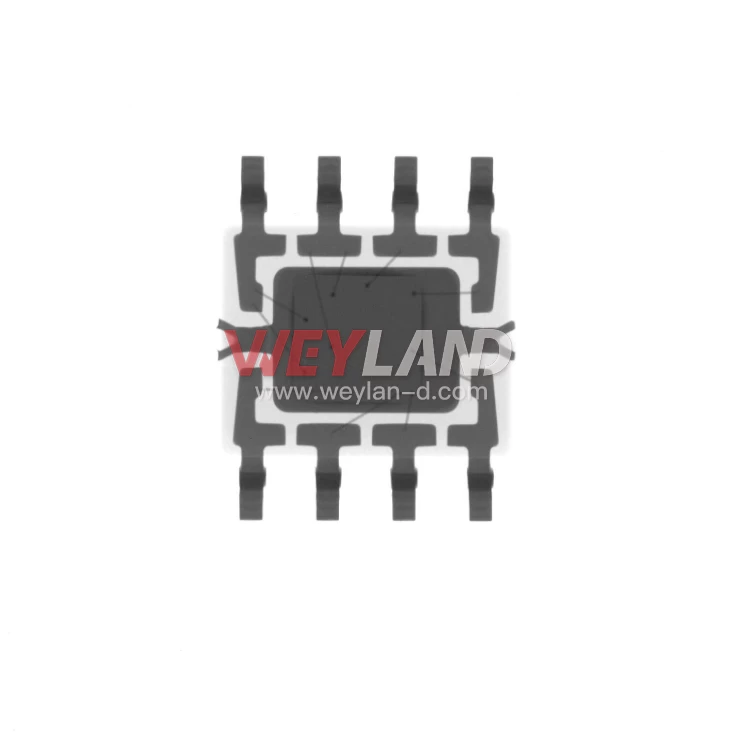

- HX711

- The HX711 is one of the most common electronic scale chips on the market, widely used for signal amplification and Analog-to-Digital Conversion (ADC) of various weighing sensors. It integrates a high-precision 24-bit ADC, capable of processing weak signals from weighing sensors, making it suitable for precision weighing equipment.

Features:

- 24-bit precision ADC for accurate weight measurement.

- Built-in gain amplifier with adjustable gain settings to improve signal processing capability.

- Supports differential input for compatibility with multiple sensors.

- Low-power mode suitable for portable electronic scale applications.

Applications: Widely used in small electronic scales, weighing devices, and sensor interface systems.

- INA333

- The INA333 is a high-precision, low-power adjustable gain amplifier commonly used in electronic scales as a signal amplifier. It features high input impedance and low noise, effectively improving the measurement accuracy of weighing sensors.

Features:

- Low noise and high input impedance for accurate signal acquisition.

- Adjustable gain for different weighing sensor ranges.

- High-precision amplifier, especially suitable for measuring weak signals.

- Low-power design, suitable for portable devices.

Applications: Suitable for various industrial-grade electronic scales, portable electronic scales, and weighing devices.

- ADS1232

- The ADS1232, developed by Texas Instruments (TI), is a 24-bit ADC chip that is ideal for weight signal acquisition in industrial electronic scales. It offers high precision, low noise, and high stability, making it widely used in precision measurement and weighing equipment.

Features:

- 24-bit precision ADC for high resolution.

- Built-in gain amplifier with multiple gain levels.

- Programmable filter to effectively remove noise and improve signal quality.

- Low-power design suitable for long-term operation in industrial equipment.

Applications: Widely used in industrial-grade electronic scales, measurement systems, and other precision instruments.

- MAX521

- The MAX521, developed by Maxim Integrated, is a 16-bit Digital-to-Analog Converter (DAC) suitable for adjusting output signals in electronic scales. It features high precision, low distortion, and low noise, ensuring stable analog output.

Features:

- High-precision 16-bit DAC for accurate output signal adjustment.

- Low noise and low distortion for stable output.

- High compatibility with various weighing sensors.

- Supports I2C and SPI interfaces for easy integration with other control units.

Applications: Suitable for precision weighing systems requiring digital control of analog output, especially for high-end industrial electronic scales.

- TLV320AIC3204

- The TLV320AIC3204, developed by Texas Instruments, is a high-precision audio codec often used in industrial control electronic scales, especially in scenarios requiring audio data acquisition and signal processing. It offers excellent noise suppression and advanced digital signal processing capabilities.

Features:

- High-performance ADC and DAC for precision signal conversion.

- Strong noise suppression to improve measurement accuracy.

- Programmable filters to adapt to different environmental interference.

- Multiple interface options for flexible integration.

Applications: Mainly used in electronic scale systems requiring high-precision digital signal processing, especially in complex industrial environments.

3. How to Select the Right Electronic Scale Chip?

When selecting IC electronic scale chips, enterprises need to consider several factors based on actual needs. The following are some key considerations when choosing a chip:

- Precision Requirements: When selecting a chip, the required precision must first be determined. Generally, 24-bit ADC chips (such as HX711, ADS1232) are suitable for high-precision electronic scale applications, while 16-bit ADC chips are more appropriate for lower precision requirements.

- Operating Environment: Consider environmental factors such as temperature, humidity, and electromagnetic interference. Choose chips with strong anti-interference capability and high-temperature stability.

- Power Consumption: For portable electronic scales, power consumption is a critical factor. Low-power chips can extend battery life.

- Interface Compatibility: The chip’s interfaces and protocols should be compatible with other components in the system for easy integration.

Conclusion

In the fields of industrial automation and intelligent control, IC electronic scale chips play a crucial role. From signal processing to data conversion, each chip directly impacts the accuracy and reliability of the electronic scale. By selecting the right chip based on specific needs, such as HX711, INA333, or ADS1232, enterprises can ensure the efficiency and stability of their electronic scale systems. With continuous technological advancements, future IC electronic scale chips will become even more intelligent and efficient, bringing more innovation and improvements to the industrial measurement field.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG