Chip-level repair technology for industrial control circuit boards

In modern industrial control, industrial control circuit boards are the core components of various automation equipment. Their stability and reliability are directly related to the normal operation of production lines. However, industrial control circuit boards are inevitably affected by factors such as the environment, load, and frequent operations, which can lead to hardware failures. Traditional replacement methods for faulty circuit boards are not only costly but also delay production. With technological advancements, chip-level repair technology for industrial control circuit boards has gradually emerged as an effective solution to this problem. It allows for quick identification and repair of faults without replacing the entire circuit board, significantly reducing repair costs and enhancing equipment stability and lifespan.

1. Concept and Advantages of Chip-Level Repair Technology

Chip-level repair technology, as the name suggests, involves diagnosing, repairing, and replacing individual chips or components on a circuit board to restore its functionality. This technology is mainly applied to the repair of circuit board-level faults, especially for issues such as damaged chips or loose solder joints. Compared to traditional methods of replacing the entire circuit board, chip-level repair offers the following advantages:

- Cost-effectiveness: Traditional repair methods typically require the replacement of the entire circuit board, while chip-level repair technology only requires repairing or replacing the damaged chip or component, significantly lowering costs.

- Improved Equipment Availability: Chip-level repair allows for fault recovery without replacing the entire circuit board, enabling quicker restoration of normal operation and reducing downtime, thus improving production efficiency.

- Extended Equipment Lifespan: Timely repairs of faults on circuit boards prevent the escalation of damage, thereby extending the equipment’s lifespan.

- Environmental Benefits: Chip-level repair technology helps reduce the amount of discarded circuit boards, in line with environmental protection requirements and contributing to less electronic waste.

2. Technical Process of Chip-Level Repair

Chip-level repair involves multiple steps, each requiring precise operation by professionals with specialized equipment. Below is the basic process of chip-level repair:

- Fault Diagnosis: The first step in chip-level repair is a comprehensive fault diagnosis of the circuit board. By using tools such as oscilloscopes and multimeters, technicians can detect parameters like voltage and current on the circuit board and pinpoint the exact location of the fault. This process requires not only theoretical knowledge but also rich practical experience.

- Disassembly and Cleaning: After confirming the fault location, technicians use specialized equipment to disassemble the circuit board and clean it. The cleaning process removes dust, dirt, and oxidation, ensuring more stable connections during the repair.

- Repair or Replacement of Damaged Chips: When a chip or component on the circuit board is damaged, technicians use tools like hot air guns and soldering stations to remove the faulty chip and install a new one. During this process, technicians must be careful to avoid damaging other components.

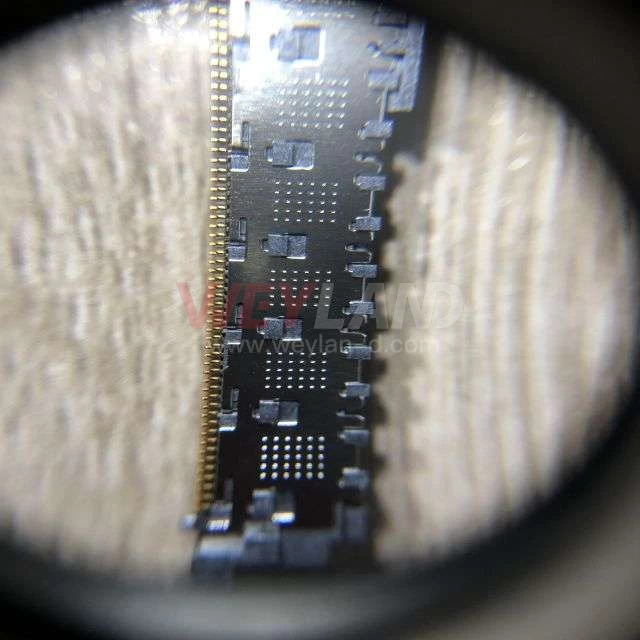

- Re-soldering and Testing: After replacing the chip, technicians use specialized soldering equipment to re-solder the connections and ensure that each solder joint meets the required standards. After soldering, the circuit board undergoes testing to verify that its functionality has been restored and the repair quality is ensured.

- Final Inspection and Validation: Once the repair is complete, technicians perform a final quality check to validate the circuit board’s stability under operational loads, ensuring the board can run stably over the long term.

3. Common Chip-Level Repair Technologies

Chip-level repair encompasses various specific repair methods, and some of the common technologies include:

- BGA (Ball Grid Array) Chip Rework Technology: BGA chips are connected to the circuit board by ball-shaped solder joints. Due to their small size and dense distribution, they are prone to issues like cold solder joints or short circuits. Using a BGA rework station, technicians can precisely reflow the solder joints of BGA chips to restore the normal operation of the circuit.

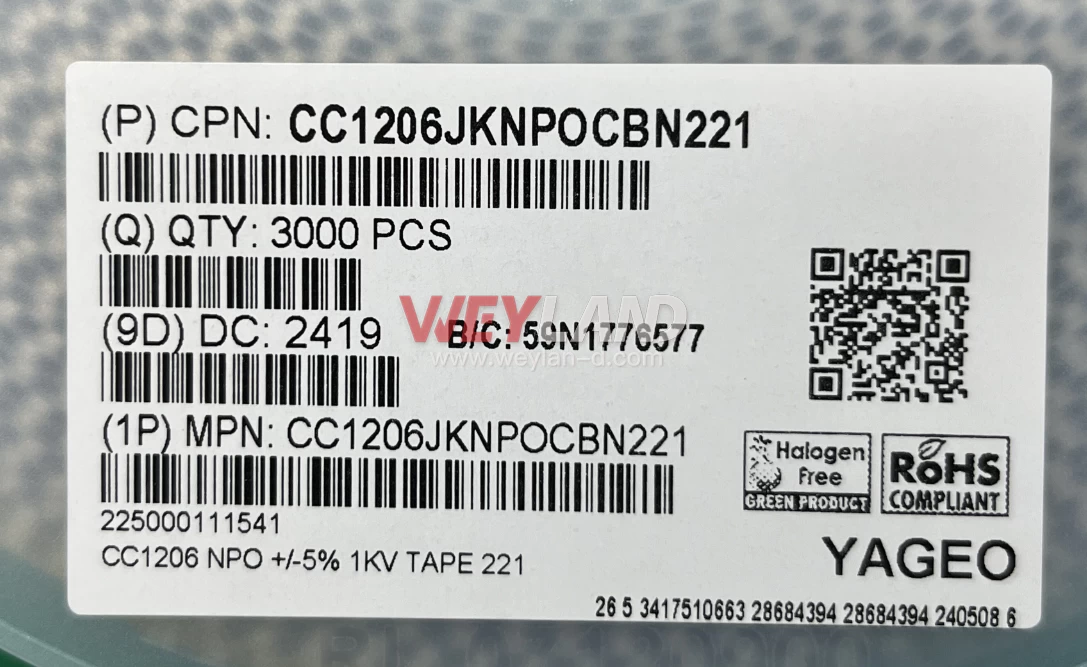

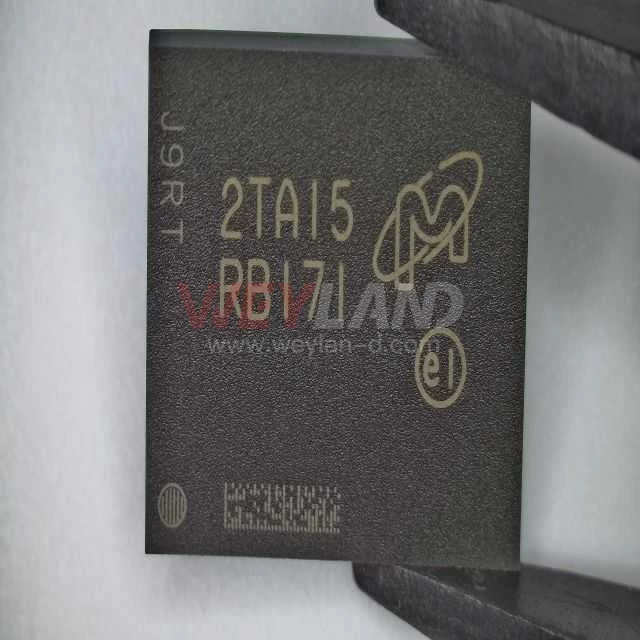

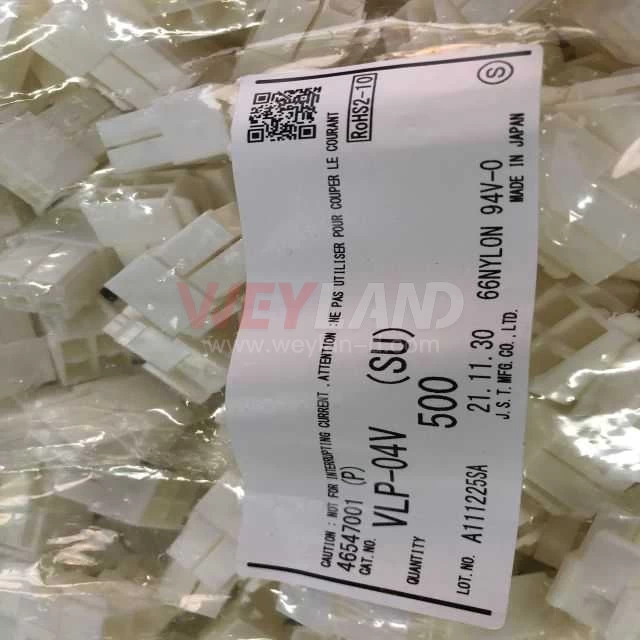

- Chip Replacement Technology: In some cases, the chip itself may be irreparably damaged, in which case it needs to be removed using specialized tools and replaced with a new chip.

- Reprogramming Technology: For circuit boards containing programmable chips (such as EPROM, FLASH, etc.), chip-level repair may also involve reprogramming the chip using a programmer to restore its functionality.

- Solder Joint Repair Technology: Many circuit board faults originate from loose solder joints between chips and components. Through precise soldering repairs, technicians can restore the connections, ensuring the circuit board operates normally.

4. Challenges in Chip-Level Repair

Although chip-level repair technology offers significant advantages, it still faces some challenges in practical application:

- High Technical Requirements: Chip-level repair requires high-precision equipment and experienced technicians. Improper operation can lead to further damage to the circuit board.

- Equipment and Material Costs: The equipment required for chip-level repair (such as BGA rework stations, hot air guns, etc.) is expensive, and the components and materials needed for repair must meet high-quality standards.

- Difficult Fault Localization: Some circuit board faults are complex, and the process of locating and repairing them can take a considerable amount of time, increasing both the difficulty and cost of repairs.

5. Conclusion

Chip-level repair technology for industrial control circuit boards is an advanced repair method that effectively addresses many of the issues with traditional repair methods, such as high costs and long downtime. With advancements in technology, chip-level repair continues to evolve, providing more precise and efficient repair services that help businesses reduce repair costs and enhance the stability and lifespan of equipment. However, chip-level repair still requires highly skilled technicians and advanced equipment. When choosing repair services, companies should prioritize professional repair institutions to ensure the quality of repairs.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG