Industrial motherboards and home computer motherboards

Differences and Connections Between Industrial Control Motherboards and Consumer Motherboards

In the realm of computer hardware, the motherboard serves as the core of all devices, connecting and coordinating the operation of various components. Industrial control motherboards and consumer motherboards, as two major types, exhibit significant differences due to their distinct application scenarios. This article delves into the differences and connections between industrial control motherboards and consumer motherboards from the perspectives of design goals, functional characteristics, and application fields.

一. Design Goals and Reliability Requirements

1. Design Goals of Industrial Control Motherboards

Industrial control motherboards are primarily used in industrial control fields, emphasizing stability, reliability, and adaptability to complex environments. To meet the stringent demands of industrial settings, these motherboards typically feature shock resistance, dustproofing, and moisture protection, allowing them to operate stably for extended periods under extreme conditions such as high or low temperatures.

2. Design Goals of Consumer Motherboards

Consumer motherboards prioritize a balance between performance and cost. Their design aims to meet the needs of home entertainment, office tasks, and gaming. These motherboards excel in multimedia capabilities, expandability, and cost-effectiveness but lack the adaptability required for harsh environments.

II. Comparison of Functional Characteristics

1. Functional Features of Industrial Control Motherboards

- High Durability: Built with high-quality components, capable of 24/7 continuous operation.

- Support for Various Interfaces: Often equipped with industrial interfaces such as RS-232, RS-485, and CAN bus to enable device communication.

- Long Supply Cycle: Designed for long-term operation and maintenance, with a supply cycle ranging from 5 to 10 years or more.

- Customization Services: Can be customized to meet specific industry or equipment requirements.

2. Functional Features of Consumer Motherboards

- High Performance and Versatility: Supports high-speed processors, discrete graphics cards, and large storage capacities, allowing seamless operation of demanding software and games.

- Strong Expandability: Offers multiple USB ports, HDMI interfaces, and other options for connecting peripherals.

- Ease of Upgrades: The fast-paced consumer market ensures compatibility with a broad range of hardware upgrades.

III. Differences in Application Fields

1. Application Fields of Industrial Control Motherboards

Industrial control motherboards are widely used in industrial automation, energy management, traffic control, medical devices, and more. For example, on automated production lines, these motherboards serve as the core control unit, connecting sensors, actuators, and supervisory systems to ensure efficient system operation.

2. Application Fields of Consumer Motherboards

Consumer motherboards are commonly found in personal computers, home media centers, gaming consoles, and similar environments. For instance, gaming enthusiasts often opt for high-performance consumer motherboards paired with advanced graphics cards to achieve smoother gaming experiences.

IV. Price and Service Comparison

Industrial control motherboards, constructed with industrial-grade materials and featuring customization and extended supply cycles, generally come at a higher price point. In contrast, consumer motherboards benefit from large-scale production and intense market competition, making them more affordable. Furthermore, industrial control motherboards offer longer-term technical support and after-sales services to ensure the smooth operation of industrial equipment. Consumer motherboards, on the other hand, focus on immediate and convenient after-sales services.

V. Conclusion

Industrial control motherboards and consumer motherboards demonstrate their respective characteristics due to differences in target audiences and operating environments. Industrial control motherboards prioritize stability and long-term reliability, serving as the core hardware in industrial control fields. Meanwhile, consumer motherboards emphasize performance and cost-effectiveness, providing comprehensive functionality for home users.

When choosing a motherboard, users should consider their specific application scenarios and needs to achieve optimal cost-effectiveness and functionality.

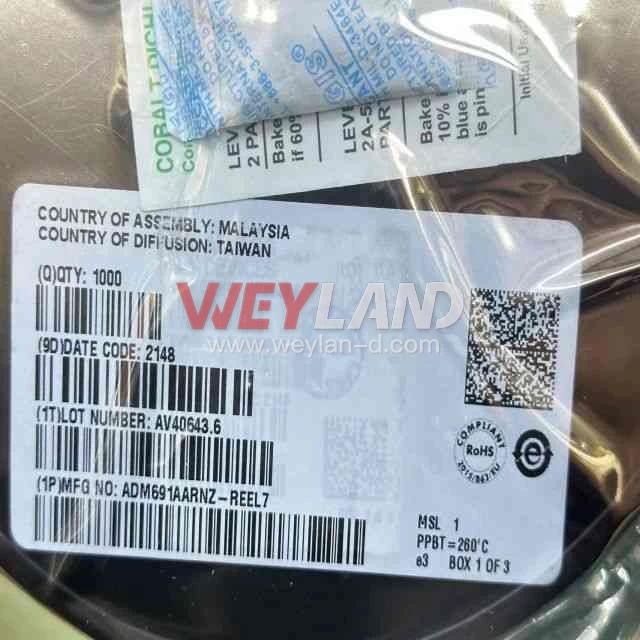

In the industrial motherboard sector, professional suppliers like WEYLAND offer high-quality industrial control motherboards. Through its online service platform, WEYLAND provides detailed product information and customized support, helping users quickly find suitable solutions.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG