Manufacturing process for medical device motherboards

In the modern medical field, the accuracy and reliability of medical devices are of paramount importance, and the manufacturing process of medical device motherboards, as their core components, requires a high degree of precision and rigor.

The manufacturing of medical device motherboards begins with the design phase. Professional electronic engineers will carry out detailed circuit design according to the specific functional requirements of medical devices. This process needs to fully consider the use of medical equipment environment, performance requirements and safety and other factors. For example, for medical devices that need to work in a high humidity environment, the design of the motherboard needs to have a good moisture-proof performance; for devices that require high-precision data processing, the motherboard needs to use high-performance chips and advanced circuit layout. After the design is completed, it will be simulated and verified by professional circuit design software to ensure the rationality and feasibility of the design.

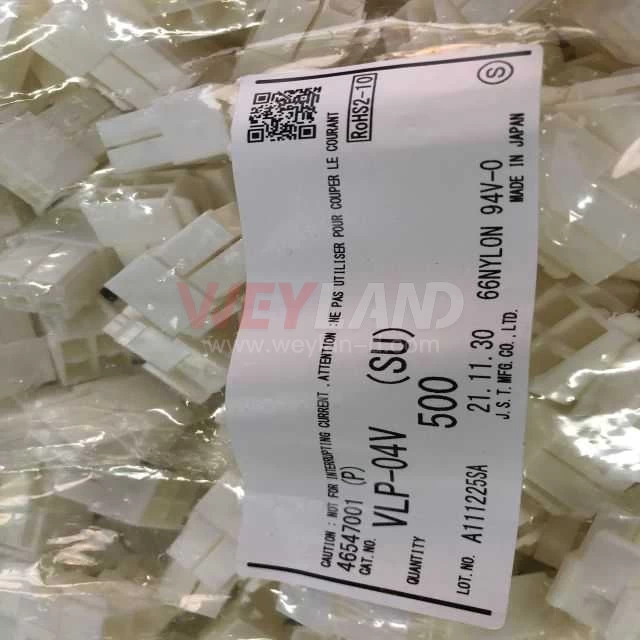

Next is the selection of raw materials. Medical device motherboards require extremely high quality of raw materials, because any small defect may affect the performance and safety of the entire medical device. Usually, high-quality electronic components, such as chips, capacitors, resistors, etc., are used, and these components need to be characterized by high stability, high precision and long life. At the same time, the material of the printed circuit board (PCB) needs to be strictly screened to ensure that it has good insulation, heat resistance and mechanical strength.

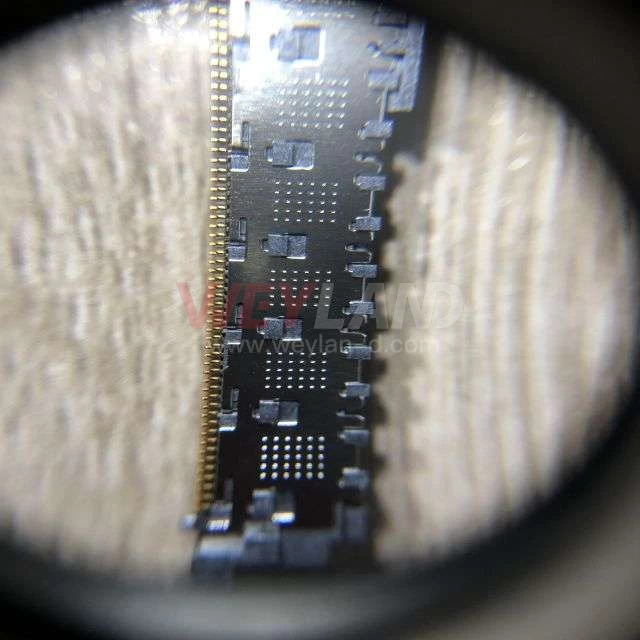

After the raw materials are prepared, the production of printed circuit boards is entered. The first step is plate making, in which the designed circuit pattern is transferred to the PCB board by photolithography. This is followed by etching, which removes unwanted copper clad sections, leaving the precise circuit lines. Next, holes are drilled in preparation for the installation of electronic components. Drilling requires a high degree of precision to ensure that the position and size of each hole is accurate. This is followed by surface treatments such as plating to improve the conductivity and corrosion resistance of the circuit board.

The mounting of electronic components is one of the key aspects of the manufacturing process. Modern medical device motherboards usually use surface mount technology (SMT), this technology can realize the high precision and high speed installation of electronic components. In the SMT process, electronic components first need to be accurately placed in the corresponding position on the PCB, and then the components are soldered to the circuit board by reflow soldering. The temperature and time of reflow soldering need to be strictly controlled to ensure the quality of soldering. At the same time, it is also necessary to carry out strict quality inspection, such as appearance inspection, electrical performance test, etc., to ensure that each component is installed correctly and good performance.

After completing the installation of electronic components, the motherboard is tested and debugged. Testing includes functional testing, performance testing, reliability testing and other aspects. Function test is mainly to verify whether the motherboard is able to realize the functions of medical equipment; performance test is to detect the processing speed of the motherboard, data transfer speed and other performance indicators; reliability test is to simulate a variety of harsh use of the environment, check the stability and reliability of the motherboard. If problems are found in the testing process, timely debugging and repair is required to ensure that the quality of the motherboard meets the requirements.

Finally, after rigorous testing of qualified medical device motherboards will be packaged and shipped. The packaging process also needs to pay attention to protect the motherboard from damage, usually using anti-static, moisture-proof packaging materials. At the same time, it will be accompanied by detailed instruction manuals and quality inspection reports to provide users with comprehensive information and protection.

In conclusion, the manufacturing process of medical device motherboards is a complex and sophisticated process that requires strict quality control and professional technical support. Only through the careful production and strict testing of each link can we produce high-quality and reliable medical device motherboards to provide solid technical support for the development of modern medical care.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG