Jiangsu Medical Device Motherboard

In the field of medical equipment, medical device motherboards from Jiangsu occupy an important position, which provides strong support for the development of medical industry with its advanced technology, reliable quality and continuous innovation.

Jiangsu medical device motherboards are rich and diverse, covering many types of medical equipment. Take the bone grafting plate as an example, there are special motherboards applicable to various fracture parts. For example, a craniomaxillofacial bone grafting plate system is used for bilateral mandibular fracture, including the first plate body, the second plate body and the third plate body which are connected in U-shape, the first plate body is connected by a plurality of the first circular plate, the second plate body is connected by a plurality of the second circular plate, and the third plate body is connected by a plurality of the third circular plate, and the third plate body is connected by a plurality of the third circular plate, which is connected in sequence. This unique design can better fit the complex shape of the craniomaxillofacial region, provide stable fixation and support for the fracture site, and help the patient's fracture healing and rehabilitation.

There is also a locking tibial medial hook-shaped plate, with one end of the plate body projecting side by side to form two hook bodies, a long groove formed between the two hook bodies, a locking hole on the surface of the other end of the plate body, a long hole on the surface of the middle part of the plate body, and a Kirschner's pin hole between the long hole and the locking hole, and a distal pointed hook structure designed to grip the medial side of the tibia bone more securely and improve the immobilization effect, which provides an effective solution for tibial bone fracture treatment.

In the field of spine treatment, Jiangsu's medical device motherboards also play an important role. For example, the composite threaded arch root nail includes two sets of main boards, with rotating rods rotatably set on the main boards, the main arch root nail set at the bottom of the rotating rods, a connecting plate set between the two sets of main boards, and a locking member and buffer balancing member at the end of the main boards for connecting the connecting plate. The spacing between the arch root staples can be flexibly adjusted by the locking member to adapt to the spinal structure and surgical needs of different patients, and the cushioning and balancing member strengthens the stability of the overall structure and reduces the discomfort of the patient in the treatment process.

The arch root staple assembly is also one of the important products of Jiangsu Medical Devices' main board. It includes two sets of fixed plates, the bottom end of the fixed plate is mounted on the base plate, there are adjusting parts between the two sets of fixed plates to control their spacing, the base plate is processed with multiple sets of positioning holes, and the arch root staple can be detachably mounted through the bolts at the positioning holes, and the cushioning and compression resistance parts are also set at the bottom of the base plate. This design allows the doctor to flexibly adjust the position of the pedicle nail according to the patient's specific situation, improving the accuracy and success rate of the operation, while the buffer anti-pressure parts can increase the fit between the device and the patient's body surface and improve stability.

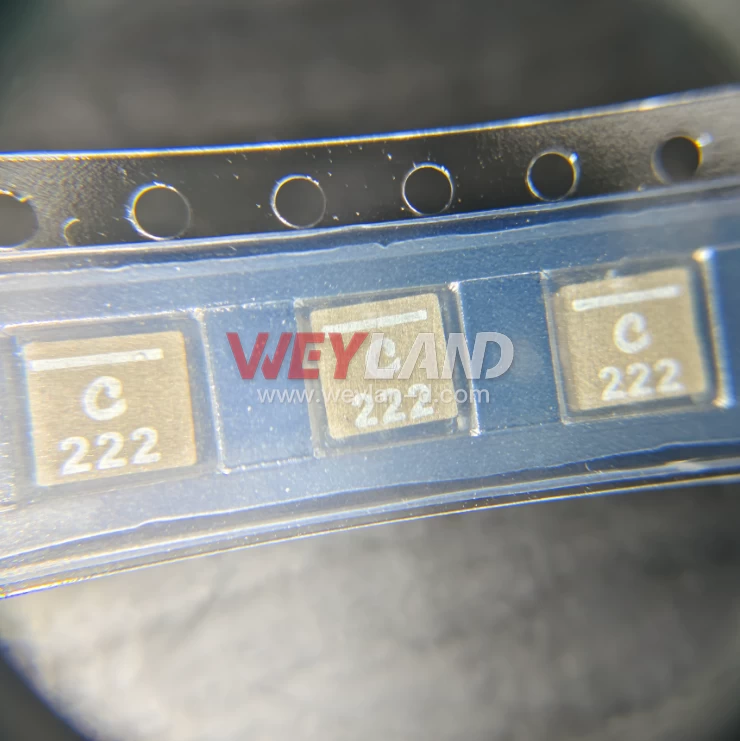

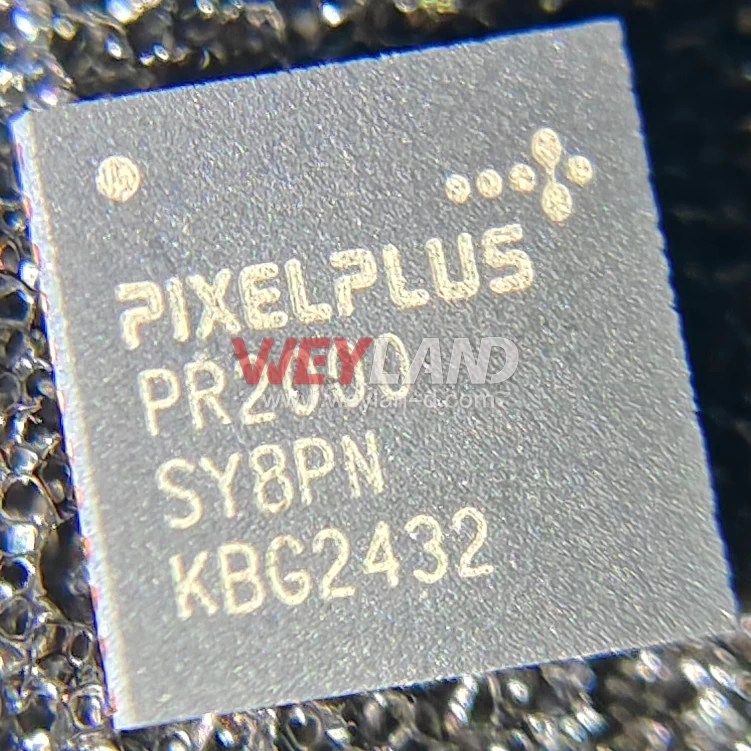

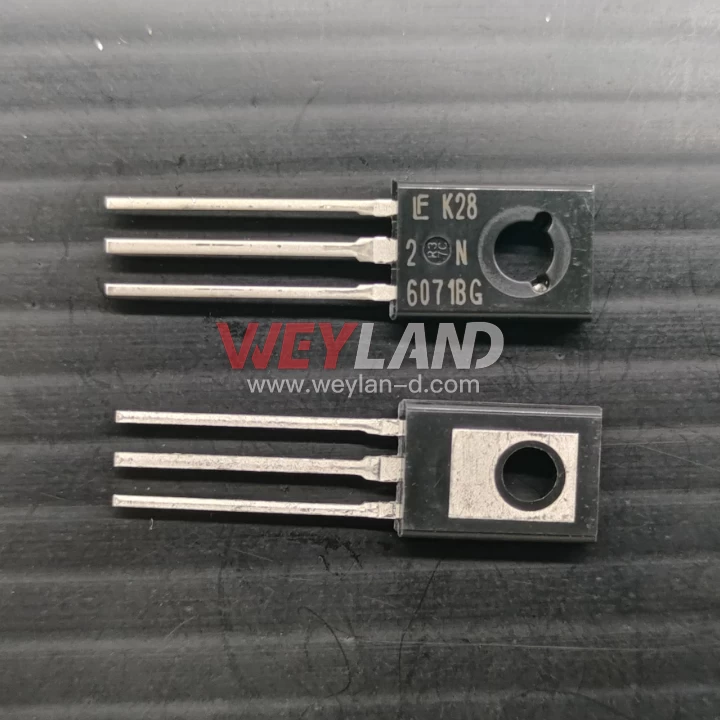

The manufacturing process of Jiangsu medical device motherboards is very rigorous. First of all, in the design stage, R&D personnel need to fully consider the special needs of medical devices, such as high stability, reliability and safety. The circuit layout should be reasonable to ensure stable and efficient signal transmission; at the same time, high-quality electronic components, such as microprocessors, memories, sensors, communication modules and so on, should be selected and subjected to strict quality testing.

During the production process, the standardized process is strictly followed, and advanced manufacturing technology and equipment are used to ensure that each motherboard meets high quality standards. For example, the connection between the electronic components and the motherboard is firmly and reliably ensured through precise welding technology; a strict quality control system is adopted to strictly test and monitor each link in the production process, so as to timely detect and eliminate potential quality problems.

The importance of Jiangsu medical device motherboard is self-evident. It is the core component of medical equipment, which directly affects the performance and function of medical equipment. Accurate data processing and analysis functions can provide doctors with accurate diagnostic information and help them develop more scientific and effective treatment plans. Reliable signal transmission and communication functions make it possible for medical devices to seamlessly interface with other devices or medical information systems to share and remotely manage medical information, providing the possibility of optimal allocation of medical resources. Stable performance and good user interface control not only ensure the normal operation of medical equipment, but also improve the operation efficiency of doctors and provide patients with more convenient and comfortable medical services.

In conclusion, with its advanced design, superb manufacturing process and reliable performance, Jiangsu medical device motherboards play an important role in the medical industry and make significant contributions to the progress of medical technology and the health and well-being of patients. With the continuous development of science and technology, we believe that Jiangsu's medical device motherboards will continue to innovate and improve, bringing more surprises and breakthroughs to the medical industry.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

- ISP co-processor

- The standard of ISP chips

- What is the power consumption level of t...

- In what scenarios can the performance of...

- Smart Home Products with Rockchip RK3588...

- Kylin ISP chip

- Purchase of ISP chips

- How fast is the read speed of Winbond W2...

- The motherboard of the industrial comput...

- spi ethernet chip in qfn package

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG