Did the price of Ethernet chips go up?

As a critical component in modern networking equipment, the price fluctuation of Ethernet chips directly affects the production cost and market price of network devices. Recently, the price of Ethernet chips has shown an upward trend, attracting widespread attention. This article will analyze the main reasons for the price increase of Ethernet chips, including supply and demand relationships, raw material costs, production technology, and market environment factors.

1. Supply and Demand

Growing Demand: In recent years, with the rapid development of data centers, cloud computing, 5G communication, and the Internet of Things, the demand for Ethernet chips has significantly increased. These emerging technologies require high-speed, stable network connections, driving the expansion of the Ethernet chip market. Especially in the context of global digital transformation, the continuous growth in demand for network equipment from both enterprises and consumers has resulted in demand for Ethernet chips exceeding production capacity.

Supply Chain Bottlenecks: At the same time, the chip production industry is facing supply chain issues that are also impacting prices. These issues include unstable supplies of manufacturing equipment and raw materials, as well as delays in logistics and transportation, all of which lead to a shortage in chip supply. The complexity of the global semiconductor supply chain further limits production flexibility and delivery capacity, driving up chip prices.

2. Raw Material Costs

Increase in Raw Material Prices: The manufacturing process of Ethernet chips requires various key raw materials, such as silicon, metal materials, and rare earth elements. In recent years, the prices of these raw materials have generally increased, directly driving up the cost of chip manufacturing. For instance, the tight supply of silicon wafers and the price fluctuations of rare earth metals have put pressure on chip production costs. The increase in raw material costs inevitably gets passed on to the final product prices.

Rising Production Costs: In addition to raw materials, other costs in the manufacturing process have also risen. The increase in energy costs, labor costs, and the expenses for maintaining and upgrading production equipment are all challenges faced by chip manufacturers. These factors collectively lead to an increase in chip production costs, which in turn drives up market prices.

3. Production Technology Challenges

Need for Technological Upgrades: To meet the demands for high speed and performance, chip manufacturers must continuously upgrade their technology and innovate. This includes developing next-generation Ethernet chip technology and improving production processes. These technological advancements require significant R&D investment and increase the complexity and cost of production. Thus, the pressure from technological progress has also contributed to the rise in chip prices.

Production Capacity Constraints: Existing chip manufacturers face challenges in expanding production capacity. Building new factories, introducing advanced equipment, and recruiting skilled personnel all require time and resources. The lack of production capacity has made it difficult for chip supply to quickly meet market demand, further driving up prices.

4. Market Environment Factors

Global Political and Economic Situation: The uncertainty in the global economy and political tensions have also affected chip prices. Factors such as trade wars and international sanctions may disrupt the supply of raw materials and equipment, driving up production costs. Additionally, the instability of the global market has increased the volatility of chip prices.

Uneven Market Demand: Demand for Ethernet chips varies across different regions and industries. Some emerging markets and fast-growing industries may demand more chips, which can cause price increases in those regions. This uneven market demand also leads to regional price fluctuations.

5. Conclusion

The price increase of Ethernet chips is the result of multiple factors. Tight supply and demand, rising raw material costs, production technology challenges, and changes in the market environment are all driving prices upward. Understanding these factors can help companies make more informed decisions in procurement and planning, while also helping market participants better cope with the challenges posed by price fluctuations. In the future, as supply chains adjust and technology continues to evolve, chip price trends may change. However, the current price increase reminds us to closely monitor the dynamic changes in the chip industry.

Please contact us if the source is mislabeled or violates your legal rights.

We will promptly correct and delete, thank you.

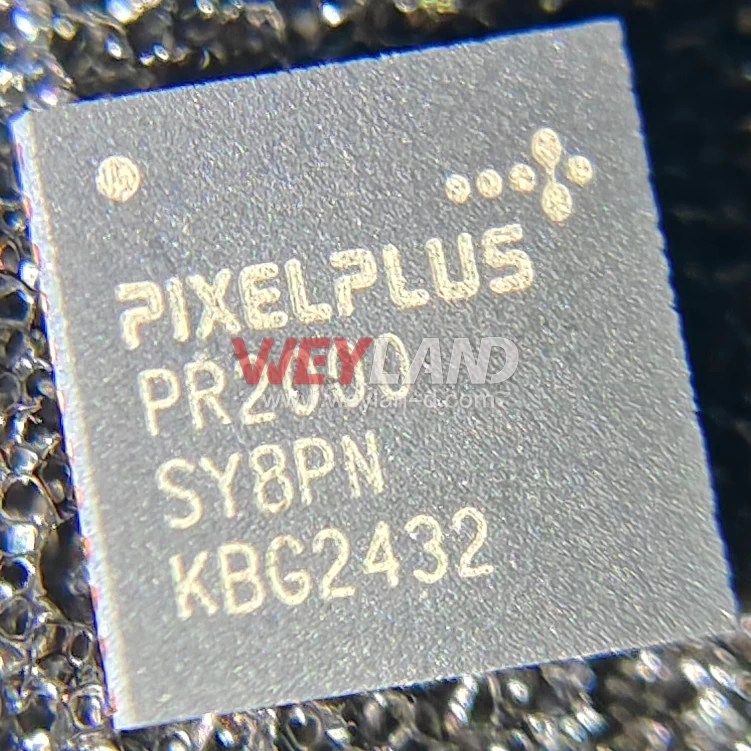

- ISP co-processor

- The standard of ISP chips

- What is the power consumption level of t...

- In what scenarios can the performance of...

- Smart Home Products with Rockchip RK3588...

- Kylin ISP chip

- Purchase of ISP chips

- How fast is the read speed of Winbond W2...

- The motherboard of the industrial comput...

- spi ethernet chip in qfn package

.9246509.png)

[email protected]

7500A BEACH ROAD #04-307 THE PLAZA SINGAPORE (199591)

RM 705.7/F.FA YUEN COMM BLDGNO.75-77.FA YUEN STREET.MONGKOK.KLN.HONG KONG